Our war on plastic education

Regular readers will remember that earlier this year I embarked on a project to help my son with a climate control school initiative, I discussed this a bit in the post on Precious Plastics. The basic idea was that I wanted to make an extruder and shredder so that we could recycle plastic waste and create 3D printing filament that the kids could then use to print things from.

From small nurdles big ideas grow

Well the project has grown a little since that initial idea and has morphed into several projects that all kind of interlink. The basic project of creating 3D printed objects from waste needed a platform to allow it to be shared to other schools. So I decided that there should be a central hub that could be used as a point of reference for teachers and parents who wanted to undertake the project for their own kids / school / college / etc. Initially this will just be my sons school but if we make it future proof it will save a bunch of work down the track. So we created the website https://nurdle.org as a central hub from which the project can be shared, discussed and supported. (Nurdles are the raw plastic pellets that a majority of plastic items are made from)

Whilst this was going on we developed an entire framework that keyed into the various learning outcomes and provided a pathway that followed the plastics lifecycle. This allowed kids to participate in various activities relating to the project that had directly relevant learning outcomes. A big part of the activities centered on the collection, identification and segregation of plastic wastes ready for processing into recycled 3D printer filament.

The TrashBin Challenge

After looking at how we could make collecting plastic trash fun and educational we realised that it could be used as a tool to help raise awareness in the wider community, so we decided to package it up as a challenge that anyone could undertake. We have launched this as a stand alone thing called the 'TrashBin Challenge' - https://trashbinchallenge.org Our hope is that the challenge will be taken up by the public which will not only help raise awareness but also provide insight into domestics plastics usage. Statistical information is collected by a simple survey of plastic waste collected by participants. In turn this statistical information can be used by the kids as part of their projects. Currently the site is in pilot with test participants but feel free to go take a look

Here's the promo video...

3D Printing directly from shredded plastic

The 3D printer filament machine has also morphed into something slightly different. Instead of creating filament that is then used in a regular 3D printer, we are trying to 3D print directly from shredded plastic. This is not without its own challenges and whilst it is not completely uncharted territory, it is still very much in its infancy. Our goal is to apply some engineering expertise to the process and improve the quality of the output, which is where other machines seem to fall down.

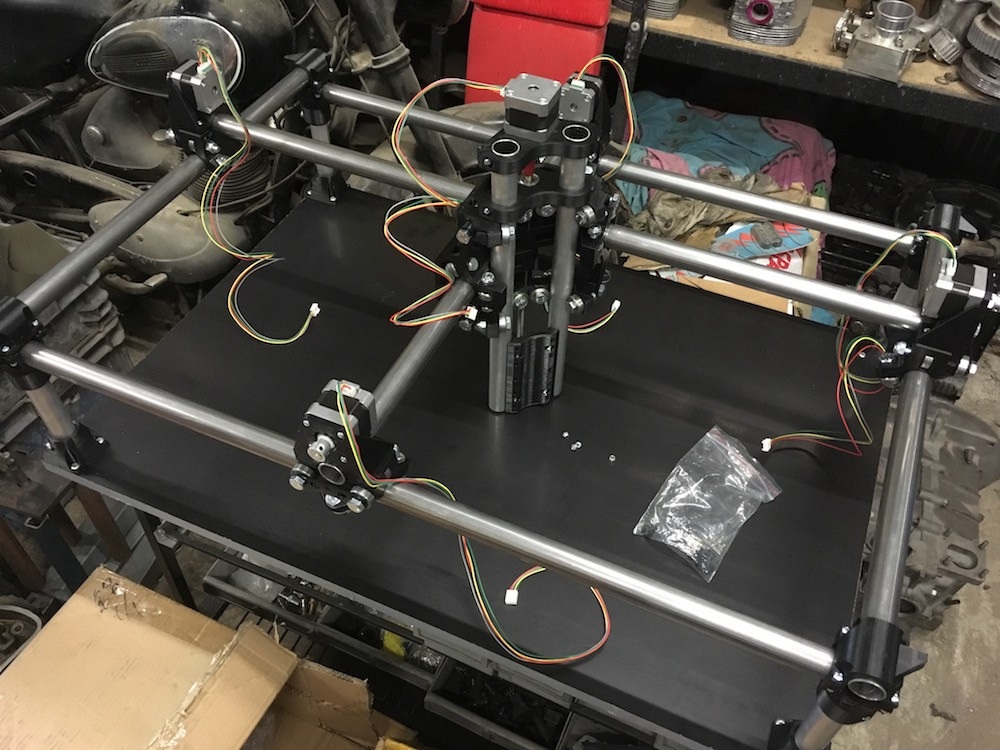

At this stage we have built a MPCNC small scale CNC machine that will be used as the basis for the 3D printer. This machine is much larger than a regular 3D printer which is necessary given that the granule extruder is physically a lot larger than the traditional filament style extruder.

We are also about half way through the development of the extruder. The design is complete but it requires a custom extruder screw to be manufactured. To do this we are making a machine from which we can make the extruder screw ourselves. It will also allow us to make design changes to the screw and improvements should we need to.

Other design issues relate to the shredder / granulator. The precious plastics shredder does not produce a small enough granule for use in our proposed extruder. This means that we are having to design our own shredder to produce granules of a suitable size. Modification of the existing Precious Plastics design did not prove to be the best pathway and a new shredder has been designed pretty much from scratch. We are also looking into a creation of a simple granulator. The granulator is probably a more appropriate type of machine for this particular application, however it is the variety of plastics which make using the granulator a challenge. If successful the granulator can be made for a fraction of the price of the shredder and can easily be scaled up for larger applications. Once the extruder has been completed this will be the next project.

Introspective

So, what started off as a simple project has snowballed into something much greater. It has also caused us to take a big look at our own plastics consumption with some scrutiny. Initially from undertaking the 'Trashbin Challenge', but then later from working on ways to overcome our relentless consumption of plastics. It's a good challenge and one that with some small changes can be fairly rewarding. We are also getting our friends on board too which is really great. We have all been feeding off of each other coming up with ideas and finding places to buy stuff that isn't wrapped in plastic. Soon, we will have the machines up and running and can finalise the educational tools too.

So if you are reading this, and are interested in reducing your plastics footprint, please go and take a look at the Trashbin Challenge. It's really easy to do and is a great way to get on board with helping the global plastics problem. Don't forget to get your friends involved too.

https://trashbinchallenge.org - 'Raising awareness of the plastics problem one TrashBin at a time.'

/DM